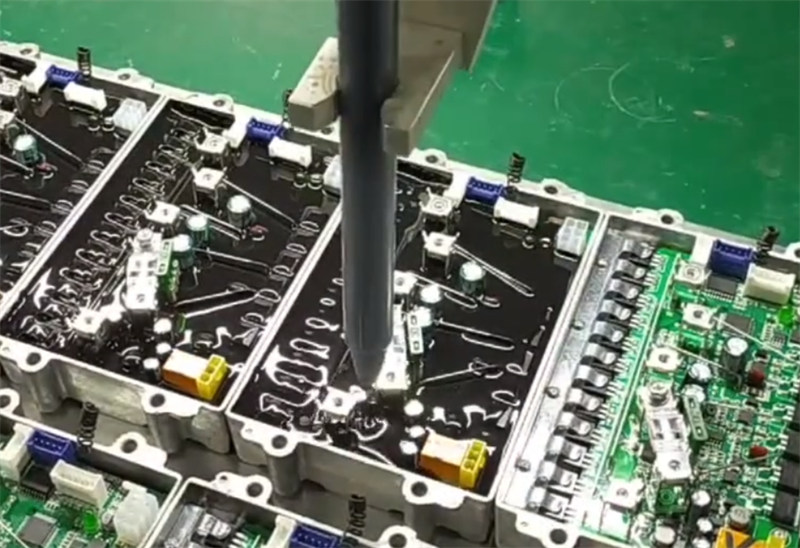

1、液体-操作时间:操作时间(也是工作时间或使用期)是固化时间的一部份,环氧树脂和固化剂按比例混合搅拌均匀之后,环氧树脂/固化剂的混合物仍然是液体,在这个状态时间内可以进行灌胶作业,灌注的胶水也有充分的时间渗透流入到被灌产品中;为了保证可靠的密封保护粘接性能,全部施工和定位工作应该在固化操作时间内做好。

2、凝胶-进入固化:混合物开始进入固化相(也称作熟化阶段),这时它开始凝胶或 “突变”;这时的环氧没有长时间的工作可能,流动性快速变差,也将失去粘性。在这个阶段不能对其进行任何干扰,它将变成硬橡胶似的软凝胶物,你用手指将能压得动它,因为这时混合物只是局部固化,新使用的环氧树脂仍然能与它化学链接,因此该未处理的表面仍然可以进行粘接或反应,无论如何,接近固化的混合物这些能力在减小。

3、固体-最终固化:环氧混合物达到固化变成固体阶段,这时能进行其它工序的作业。这时的胶体已慢慢表现出较高的硬度至最终固化硬度,在这时环氧树脂约有70%-90%的最终反应强度,因此可以除去固定夹件,将它放在室温下维持若干天使它继续后固化。这时新使用的环氧树脂不能与它进行化学链接,因此该环氧表面必须适当地进行预处理如打磨,才能得到好的粘接机械强度。

1. Liquid operation time: the operation time (also the working time or service life) is a part of the curing time. After the epoxy resin and curing agent are mixed in proportion, the mixture of epoxy resin and curing agent is still liquid. In this state, glue pouring can be carried out, and the poured glue has sufficient time to permeate into the poured product All construction and positioning work should be done well within the curing operation time.

2, gel - enter curing: the mixture begins to enter the curing phase (also known as ripening stage), when it starts to gel or "mutate"; at this time, epoxy does not work for a long time, and the mobility will rapidly become worse, and it will lose viscosity. No interference can be made at this stage, it will become a hard rubber soft gel, and you can press it with your fingers, because the mixture is only locally cured, and the new epoxy resin can still be chemically linked with it, so the untreated surface can still be used for bonding or reaction, and in any case, these abilities near the solidified mixture are decreasing.

3. Solid final curing: the epoxy mixture reaches the stage of curing into solid, at which time other processes can be carried out. At this time, the colloid has gradually shown a higher hardness to the final curing hardness. At this time, the epoxy resin has about 70% - 90% of the final reaction strength. Therefore, the fixed clamp can be removed and kept at room temperature for several days. It will continue to cure after curing. At this time, the newly used epoxy resin can not be chemically linked with it, so the epoxy surface must be properly pretreated, such as grinding, to obtain good bonding mechanical strength.

东莞市华创电子材料有限公司/东莞市华创绝缘材料有限公司/昆山市华创电子材料有限公司

专业的胶粘剂研发生产企业!始于1999年,因为专业,相信我们会做得更好!。

环氧树脂胶,电子灌封胶,结构胶,单组份环氧树脂胶,环氧AB胶,密封胶,UV胶,导电/导磁/耐高温/阻燃环氧胶,胶粘剂定制,邦定胶,电子胶水,红胶,黑胶,白胶,磁芯胶,SMT红胶,底填胶,低温快固化环氧,胶粘剂,胶黏剂,UL胶水;联络人:王先生 电话:13712306987 (微信号同)。

发表评论