AB胶是两液混合硬化胶的别称,一液是本胶(树脂组份或A组份),一液是固化剂/硬化剂(B组份),两液相混才能固化/硬化,AB胶是双组分胶粘剂的叫法。

常见的AB胶

环氧树脂AB胶,聚氨酯AB胶,有机硅AB胶,丙烯酸AB胶,其它结构型AB胶等

那么,AB胶一般的使用操作正确的步骤是什么样的呢?下面我们来了解一下

1、器具:推荐用硬壁硬底的容器和宽扁的搅拌工具(专业的搅拌机器更好)

保证器具干燥无异物,调胶后尽快进行清洗(可用酒精或洗洁剂进行清洗器具)

2、配比:AB组份胶水须按重量比进行混合(这个重量比厂家都会有明确的标识) ,偏差建议小于5%

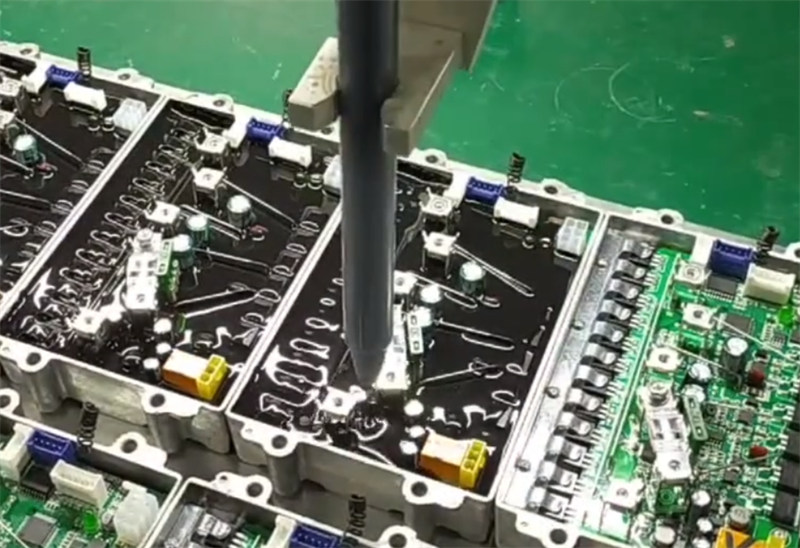

3、搅拌:胶水配比混合后,搅拌要充分均匀,保证容器的各个部位都要搅拌到位(搅胶时间没有特别限定,充分混合均交即可,所有部位色泽一致、浓度一致可定为均匀);灌封胶在搅拌后推荐抽一下真空,这样灌封出的产品外观、性能更佳。

4、上胶:操作时间较长的胶水在搅拌后放致几分钟在进行点胶灌封操作效果会更好;粘接或灌封的产品部位保证清洁、干燥(水下粘接胶水除外),灌封线较密或大型产品时,推荐灌封分两到三次进行,这样可以降低气泡出现的可能性。

5、固化:胶水点/灌好后,放于平整、通风、阴凉处让其自然固化;若要加温固化最好在点/灌后10-30分钟后放入加温为佳,加温方式最好用缓慢加温法,也可分温度段进行加温(先低温烤到初固,再高温烤)

6、其它:灌封类AB胶可用灌胶机、点胶机、针筒等进行操作,粘接类AB胶可用AB胶管、点胶机、针筒、塑胶袋等进行操作

使用过程中都有哪些注意事项呢?

1、施胶部位保持清洁,干燥;使用胶水前先小量试用掌握技巧;

2、工作场所保持阴凉通风,过敏人员尽量不直接操作或做好相关防护;

3、本品对眼睛、皮肤有轻微刺激性,如若不小心溅入眼睛,请立刻用大量水冲洗,情况严重者请立即就医;皮肤上可用肥皂水洗或酒精擦除;

4、存放时间较长的胶水(保质期内),用前先充分搅拌均匀后再使用;

5、胶水固化速度与配胶量多少、环境温度有关,胶量越多、温度越高则固化越快,因此,配胶时应根据实际合理调整配胶量,以防浪费;

6、配合比例应依规定按重量配比,不可随意调整或有较大误差,AB组份应充分混合搅拌均匀,以免造成胶水不固化或固化不完全;

7、固化剂成份有吸潮之特性,吸潮严重会造成固化物表面不光或产生油面,此时选择适当加温可以避免此类现象发生;固化剂储存要密封;

8、胶水不能同其它溶剂或液体混用,以免产生不可预知的产品问题。

AB glue is another name of two-liquid mixed hardener. One is the adhesive (resin component or component a), the other is curing agent / hardener (component B). Only when two liquids are mixed can it be cured / hardened. AB adhesive is the name of two-component adhesive.

Common AB glue

Epoxy resin AB adhesive, polyurethane AB adhesive, silicone AB adhesive, acrylic acid AB adhesive, other structural type AB adhesive, etc

So, what is the correct procedure for general use and operation of AB glue? Let's take a look at it

1. Utensils: it is recommended to use containers with hard wall and hard bottom and wide and flat mixing tools (professional mixing machines are better)

Ensure that the appliance is dry and free of foreign matters, and clean it as soon as possible after mixing glue (the appliance can be cleaned with alcohol or detergent)

2. Proportioning: ab component glue must be mixed according to the weight ratio (the weight ratio will be clearly marked by the manufacturer), and the deviation is recommended to be less than 5%

3. Mixing: after mixing the glue, the mixing should be fully and evenly to ensure that all parts of the container are stirred in place (there is no special limit for the mixing time, full mixing can be delivered, and all parts with the same color and concentration can be regarded as uniform); it is recommended to vacuum the potting glue after mixing, so that the appearance and performance of the potted products will be better.

4. Gluing: glue with longer operation time is better after mixing for a few minutes before dispensing and pouring. The bonding or sealing parts of products shall be kept clean and dry (except for underwater adhesive glue). When the pouring line is dense or large products, it is recommended to conduct pouring and sealing in two or three times, so as to reduce the possibility of bubbles.

5. Curing: put the glue in a flat, well ventilated and cool place for natural curing; if it needs to be heated and solidified, it is better to put it into the heating 10-30 minutes after the point / pouring. The heating method is better to use the slow heating method, or it can be heated by different temperature sections (first low temperature baking to initial setting, then high temperature baking)

6. Others: pouring type AB glue can be operated by pouring machine, dispensing machine and needle cylinder, while adhesive type AB glue can be operated by ab hose, dispensing machine, syringe, plastic bag, etc

东莞市华创电子材料有限公司/东莞市华创绝缘材料有限公司/昆山市华创电子材料有限公司

专业的胶粘剂研发生产企业!始于1999年,因为专业,相信我们会做得更好!。

环氧树脂胶,电子灌封胶,结构胶,单组份环氧树脂胶,环氧AB胶,密封胶,UV胶,导电/导磁/耐高温/阻燃环氧胶,胶粘剂定制,邦定胶,电子胶水,红胶,黑胶,白胶,磁芯胶,SMT红胶,底填胶,低温快固化环氧,胶粘剂,胶黏剂,UL胶水;联络人:王先生 电话:13712306987 (微信号同)。

发表评论