胶接理论之机械结合理论

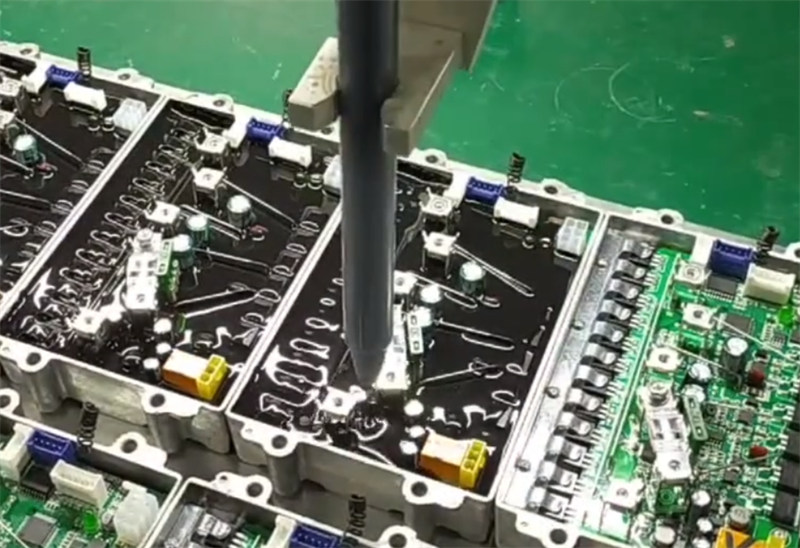

机械结合理论是最早提出的理论。理论认为,胶接只是一个机械结合过程,是胶黏剂对两个被粘物的粘接面机械附着作用的结果。它是以所有固体表面均为粗糙、多孔为基础,当胶黏剂流动、扩散、渗入、填满凹凸不平、细小孔隙的被粘物表面后,一旦胶凝固或固化,胶与被粘物表面便通过互相的咬合而连接起来,形成了无数微小胶黏剂的“钉键”“钩键”“根键”“榫键”,把两个被粘物牢牢地结合在一起。因此,机械结合理论认为:胶钉越多,胶黏剂渗透得越深,孔隙填充越满,胶接强度越高。

很明显,机械结合力对胶接强度的贡献与被粘物材料的表面状态有关。对金属特别是玻璃等表面缺陷比较小的材料的粘接,机械结合力对粘接强度贡献甚小;而对海绵、泡沫塑料、织物、纸张等多孔性材料的粘接,机械结合力则占主导地位;对非极性的多孔材料的粘接,机械结合力则起着决定性作用。因此,机械结合理论不能解释非多孔性,如表面光滑的玻璃等物体的胶接现象,不能解释许多胶接现象,具有一定的局限性。

Mechanical bonding theory of bonding theory

Mechanical combination theory is the first theory. According to the theory, bonding is only a mechanical bonding process, which is the result of mechanical adhesion of adhesive to the bonding surface of two adherents. It is based on the fact that all solid surfaces are rough and porous. When the adhesive flows, diffuses, penetrates, and fills the uneven and small pores on the surface of the adherent, once the adhesive solidifies or solidifies, the adhesive and the surface of the adherent will be connected by mutual occlusion, forming countless tiny adhesive "nail bond", "hook bond", "root bond" and "tenon bond", Hold the two adherents together firmly. Therefore, according to the mechanical bonding theory, the deeper the adhesive penetrates, the fuller the pore is filled, and the higher the bonding strength is.

东莞市华创电子材料有限公司/东莞市华创绝缘材料有限公司/昆山市华创电子材料有限公司

专业的胶粘剂研发生产企业!始于1999年,因为专业,相信我们会做得更好!。

环氧树脂胶,电子灌封胶,结构胶,单组份环氧树脂胶,环氧AB胶,密封胶,UV胶,导电/导磁/耐高温/阻燃环氧胶,胶粘剂定制,邦定胶,电子胶水,红胶,黑胶,白胶,磁芯胶,SMT红胶,底填胶,低温快固化环氧,胶粘剂,胶黏剂,UL胶水;联络人:王先生 电话:13712306987 (微信号同)。

发表评论