环氧树脂胶粘剂是以环氧树脂为主体配制而成的。树脂大分子末端有环氧基,链间有羟基和醚键,并在固化过程中还会继续产生羟基和醚键,结构中含有苯环和杂环,这些结构决定了环氧树脂胶粘剂具有优异的性能。环氧树脂胶粘剂是一种使用历史较久,用途极其广泛的胶粘剂。由于其强度、多样性和对多种多样的被粘表面具有优异的粘合力,环氧树脂胶粘剂得到了广泛用户的认同。它们已经参与和加快了某些工业部门的技术革命。环氧树脂可用于粘接金属、玻璃、陶瓷、许多塑料、木材、混凝土及其他一些表面。在美国生产的环氧树脂中,10%以上用作胶粘剂。过去,人们对环氧树脂的改性一直局限于橡胶方面,如端羧基丁腈橡胶、端羟基丁腈橡胶、聚硫橡胶等。近年来,对环氧树脂的改性不断深入,改性方法日新月异,如互穿网络法、华创材料-始于1999年,专注胶粘剂新材料研发生产,因为专业相信我们会做得更好!化学共聚法等,尤其是液晶增韧法和纳米粒子增韧法更是近年来研究的热点。随着“规模化、高纯化、精细化、专用化、系列化、功能化”发展模式的确立,环氧树脂的改性研究日新月异,目前已形成业内关注的焦点,它将促使环氧树脂在经济建设和人们生活中进一步越来越广泛地得到应用。

环氧树脂胶粘剂的品种繁多,其分类的方法和分类的指标尚未统一。通常按下列方法分类。按胶粘剂的形态分类:如无溶剂型胶粘剂、(有机)溶剂型胶粘剂、水性胶粘剂(又可分为水乳型和水溶型两种)、膏状胶粘剂、薄膜状胶粘剂(环氧胶膜)等。

按固化条件分类:冷固化胶(不加热固化胶)。又分为低温固化胶,固化温度<15℃;室温固化胶,固化温度15~40℃;热固化胶又可分为:中温固化胶,固化温度约80~120℃;高温固化胶,固化温度>150℃;其他方式固化胶,如光固化胶、潮湿面及水中固化胶、潜伏性固化胶等。

按胶接强度分类:结构胶抗剪及抗拉强度大,而且还应有较高的不均匀扯离强度,使胶接接头在长时间内能承受振动、疲劳及冲击等栽荷。同时还应具有较高的耐热性和耐候性;次受力结构胶能承受中等载荷,通常抗剪强度17~25Mpa,不均匀扯离强度20~50kN/m;非结构胶,即通用型胶粘剂。其室温强度还比较高,但随温度的升高,胶接强度下降较快。只能用于受力不大的部位。

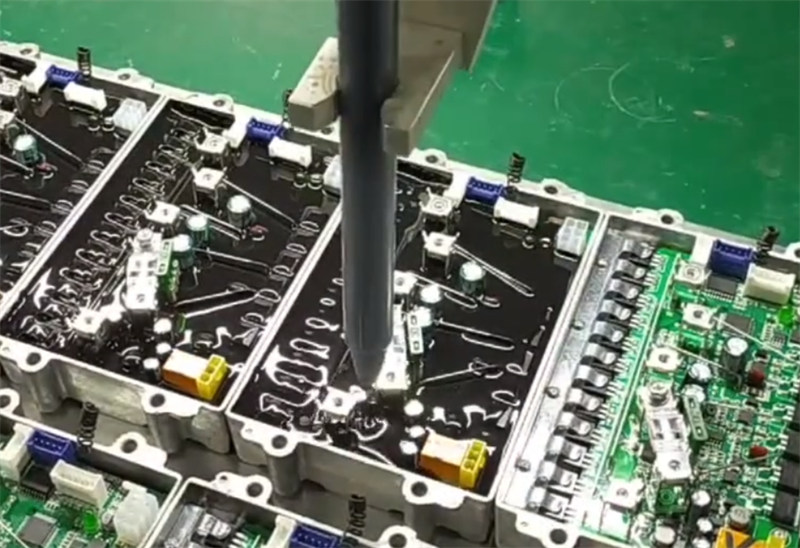

按用途分类:通用型胶粘剂,特种胶粘剂,如耐高温胶(使用温度≥150℃)、耐低温胶(可耐-50℃或更低的温度)、应变胶(粘贴应变片用)、导电胶、密封胶(真空密封、机械密封用)、光学胶(无色透明、耐光老化、折光率与光学零件相匹配)、耐腐蚀胶、结构胶等。也可按固化剂的类型来分类,如胺固化环氧胶、酸酐固化胶等。还可分为双组分胶和单组分胶,纯环氧胶和改性环氧胶。

Epoxy resin adhesive is made of epoxy resin. There are epoxy groups at the end of the macromolecules, hydroxyl and ether bonds between the chains, and hydroxyl and ether bonds will continue to be generated during the curing process. The structure contains benzene ring and heterocycle, which determines the excellent properties of the epoxy resin adhesive. Epoxy resin adhesive is a kind of adhesive which has been used for a long time and is widely used. Because of its strength, diversity and excellent adhesion to a variety of bonded surfaces, epoxy resin adhesive has been widely recognized by users. They have participated in and accelerated the technological revolution in some industrial sectors. Epoxy resin can be used to bond metal, glass, ceramics, many plastics, wood, concrete and other surfaces. More than 10% of the epoxy resins produced in the United States are used as adhesives. In the past, the modification of epoxy resin has been limited to rubber, such as carboxyl terminated nitrile rubber, hydroxyl terminated nitrile rubber, polysulfide rubber and so on. In recent years, the modification of epoxy resin continues to deepen, and the modification methods change rapidly, such as IPN method, Huachuang materials - started in 1999, focusing on the R & D and production of new adhesive materials, because we believe that we will do better! In recent years, chemical copolymerization, especially liquid crystal toughening and nano particle toughening, has become a research hotspot. With the establishment of the development mode of "large-scale, high purification, refinement, specialization, serialization and functionalization", the modification research of epoxy resin is changing with each passing day. At present, it has become the focus of the industry. It will promote the further and more extensive application of epoxy resin in economic construction and people's life.

东莞市华创电子材料有限公司/东莞市华创绝缘材料有限公司/昆山市华创电子材料有限公司

专业的胶粘剂研发生产企业!始于1999年,因为专业,相信我们会做得更好!。

环氧树脂胶,电子灌封胶,结构胶,单组份环氧树脂胶,环氧AB胶,密封胶,UV胶,导电/导磁/耐高温/阻燃环氧胶,胶粘剂定制,邦定胶,电子胶水,红胶,黑胶,白胶,磁芯胶,SMT红胶,底填胶,低温快固化环氧,胶粘剂,胶黏剂,UL胶水;联络人:王先生 电话:13712306987 (微信号同)。

发表评论