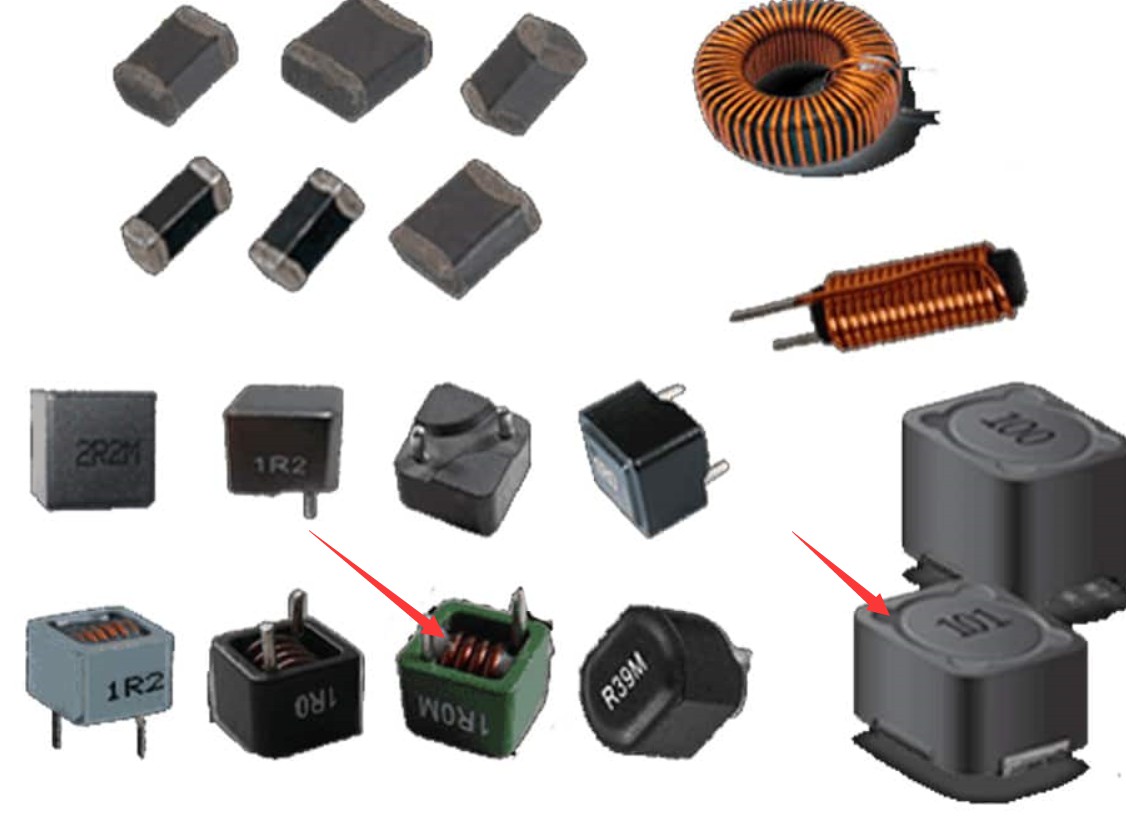

电感线圈是利用电磁感应的原理进行工作的器件。当有电流流过一根导线时,就会在这根导线的周围产生一定的电磁场,而这个电磁场的导线本身又会对处在这个电磁场范围内的导线发生感应作用。对产生电磁场的导线本身发生的作用,叫做“自感“,即导线自己产生的变化电流产生变化磁场,这个磁场又进一步影响了导线中的电流;对处在这个电磁场范围的其他导线产生的作用,叫做“互感“。

电感线圈的电特性和电容器相反,“通低频,阻高频“。高频信号通过电感线圈时会遇到很大的阻力,很难通过;而对低频信号通过它时所呈现的阻力则比较小,即低频信号可以较容易的通过它。电感线圈对直流电的电阻几乎为零。

市面上电子灌封胶密封胶类型繁多,很多朋友不知道用于电感线圈的灌封密封胶该选择哪种,针对这一点华创材料来给大家来介绍一下:

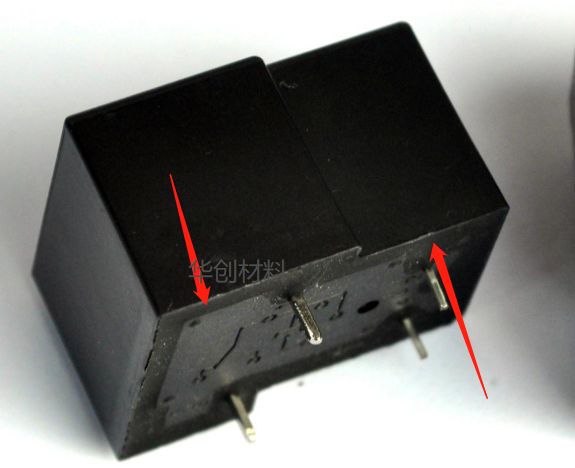

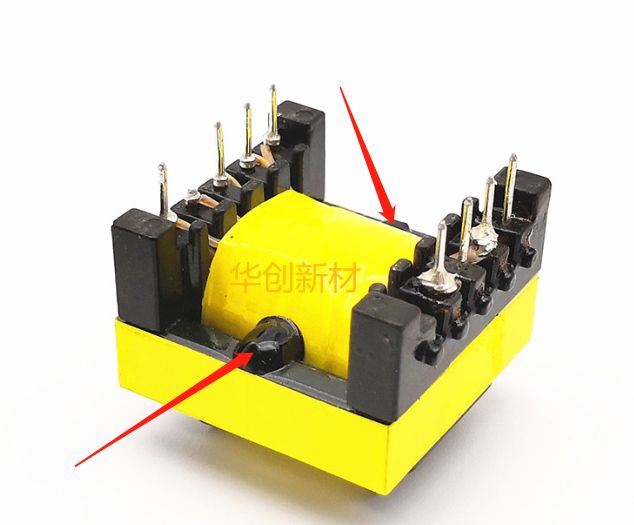

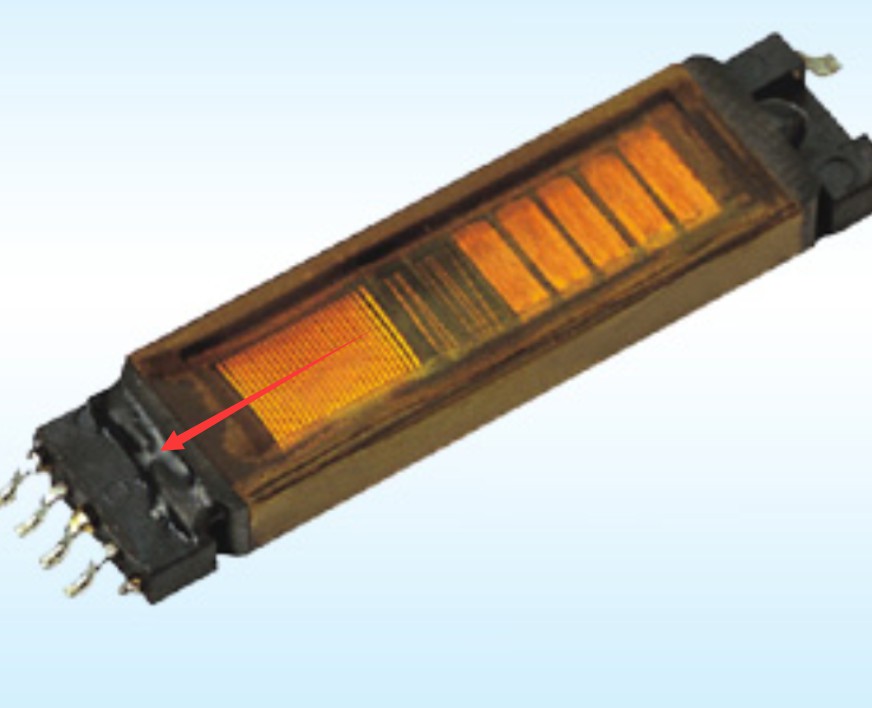

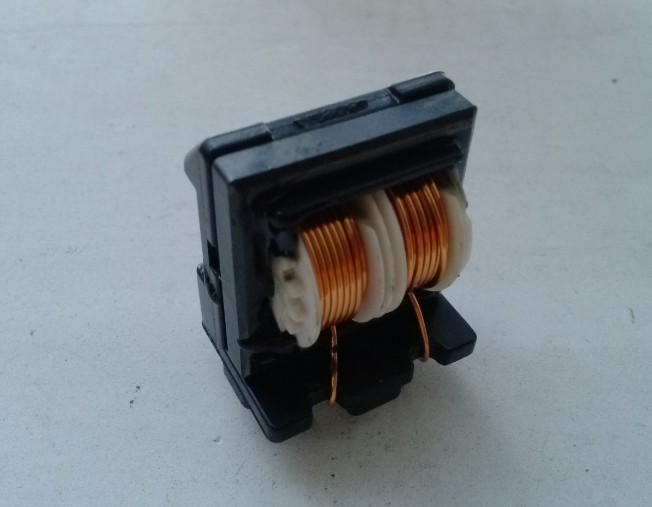

电感线圈广泛应用于电器产品上,一般导线需要缠绕次数多,www.cnepoxy.cc 且导线粗细程度低。作为一种常见电子元器件,常见的的质量问题就是线圈之间的短路、导线的断裂、发热的影响。一般来说,保证电感线圈的质量,能很好的提高相关产品的质量水平。除开线圈漆包线的因素影响,主要是对线圈进行胶水的灌封处理。电感线圈灌封胶既可以对线圈起到绝缘的作用,电感线圈灌封也能对线圈的固定,防止振动带来电器产品的质量问题。

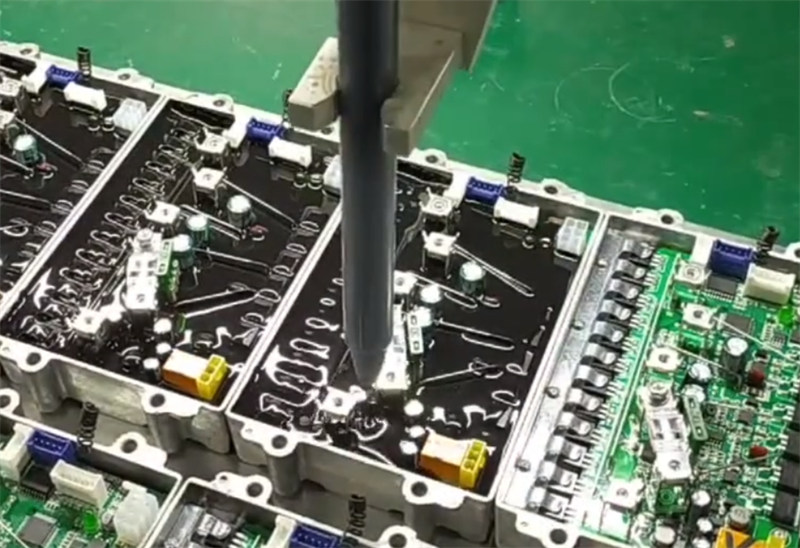

现推荐两款华创材料-电感线圈灌封胶水产品供选用参考:(还有其它功能性的,如导热,耐高温,软性等特性的,可以点开主页进行查看或 www.hcglue.com/?cate=10 )

808AB系双剂型环氧树脂绝缘密封材料,广泛应用于电子零组件、电子变压器、充电桩、滤清器、负离子发生器、电容、电源模块、LED模组、线路元件、水族水泵、电力电器部件、汽车零部件、机电五金、光电灯饰等的绝缘灌注、粘接、防潮封填等。混合后黏度低、流动性强且具有适当的可操作时间,易于生产作业。固化物收缩性低、表面光亮、坚硬、附着力及密封性强,耐化学品特性优良,具有优良的电气特性与物性。

固化前参数:

主剂808A

外 观 黑、灰、白等色液体

比 重 1.50±0.05

粘度(25) 6000-8000cps

固化剂808B

外 观 褐色液体

比 重 1.05±0.05

粘度(25) 70-150cps

混合比例: A :B = 5 : 1 (重量比)

808AB-H系双剂型阻燃环氧树脂绝缘密封材料UL认证,广泛应用于电子零组件、电子变压器、充电桩、滤清器、负离子发生器、电容、电源模块、LED模组、线路元件、水族水泵、电力电器部件、汽车零部件、机电五金、光电灯饰等的绝缘灌注、粘接、防潮封填等。混合后黏度低、流动性强且具有适当的可操作时间,易于生产作业。固化物收缩性低、表面光亮、坚硬、附着力及密封性强,符合阻燃标准,耐化学品特性优良,具有优良的电气特性与物性。

固化前参数:

主剂808A-H

外 观 黑、灰、白等色液体

比 重 1.50±0.05

粘度(25) 7000-9000cps

固化剂808B-

外 观 褐色液体

比 重 1.05±0.05

粘度(25) 70-150cps

混合比例: A :B = 5 : 1 (重量比)

The inductance coil is a device which uses the principle of electromagnetic induction to work. When a current flows through a wire, a certain electromagnetic field will be generated around the wire, and the wire of the electromagnetic field will induce the wire in the electromagnetic field range. The effect on the conductor that produces electromagnetic field is called "self induction", that is, the changing current generated by the conductor itself produces a variable magnetic field, which further affects the current in the conductor; the effect on other wires within the electromagnetic field range is called "mutual inductance".

The electrical characteristic of inductance coil is opposite to that of capacitor. When the high-frequency signal passes through the inductance coil, it will encounter great resistance, and it is difficult to pass through it; while for the low-frequency signal, the resistance is relatively small, that is, the low-frequency signal can easily pass through it. The resistance of inductance coil to DC current is almost zero

There are many types of electronic potting sealant on the market. Many friends don't know which sealing sealant to choose for inductance coil. In view of this, Huachuang materials will introduce to you:

Inductor coil is widely used in electrical products. Generally, the wire needs to be wound many times, www.cnepoxy.cc And the wire thickness is low. As a kind of common electronic components, the common quality problems are the short circuit between coils, the fracture of wires and the influence of heating. Generally speaking, to ensure the quality of inductance coil can improve the quality level of related products. In addition to the factors affecting the coil enameled wire, the main factor is to seal the coil with glue. The potting glue of inductance coil can not only insulate the coil, but also fix the coil, so as to prevent the quality problems of electrical products caused by vibration.

Two types of Huachuang materials - inductance coil pouring glue products are recommended for reference: (there are other functional, such as heat conduction, high temperature resistance, soft and other characteristics, you can click the home page to view or www.hcglue.com/?cate=10 )

808ab series of double dosage epoxy resin insulation and sealing materials are widely used in insulation pouring, bonding and moisture-proof sealing of electronic components, electronic transformers, charging piles, filters, anion generators, capacitors, power supply modules, LED modules, circuit components, water pumps, power electrical components, automobile parts, mechanical and electrical hardware, photoelectric lighting, etc. After mixing, the viscosity is low, the fluidity is strong, and the operation time is appropriate. The cured product has low shrinkage, bright surface, hard, strong adhesion and sealing, excellent chemical resistance, and excellent electrical and physical properties.

东莞市华创电子材料有限公司/东莞市华创绝缘材料有限公司/昆山市华创电子材料有限公司

专业的胶粘剂研发生产企业!始于1999年,因为专业,相信我们会做得更好!。

环氧树脂胶,电子灌封胶,结构胶,单组份环氧树脂胶,环氧AB胶,密封胶,UV胶,导电/导磁/耐高温/阻燃环氧胶,胶粘剂定制,邦定胶,电子胶水,红胶,黑胶,白胶,磁芯胶,SMT红胶,底填胶,低温快固化环氧,胶粘剂,胶黏剂,UL胶水;联络人:王先生 电话:13712306987 (微信号同)。

发表评论